As sustainability takes centre stage in boardroom discussions, industry stakeholders are implementing innovative eco-friendly initiatives. This article highlights some of the key developments shaping the path towards a greener future.

Hueck Folien is making strides in advancing the sustainability of its products and aims to achieve ecologically neutral production by 2035. In the August issue of HN, we covered the company’s initiatives, including its use of high-purity recycled aluminium and collaboration with Joanneum Research (JR) to develop bio-based optical films through the FlexFunction2Sustain project.

The company has now announced a significant investment in a new high- vacuum vapour deposition plant designed for metallising plastic films.

This new system will allow Hueck Folien to precisely vaporise metals such as aluminium and apply extremely thin layers to its films at a production speed of 1000 meters per minute. The new machine can keep the thickness of the metal layer constant at +/- two nanometres, ie., around 20 atomic layers. The total investment for the vapour deposition system, a new production building, and logistics upgrades amount to €8.6 million.

The expansion will involve adding 400m2 to the production area, converting part of the existing warehouse into a manufacturing hall, and constructing a new production facility. The strategic location near the existing metallisation area will optimise material and energy supply logistics for the new plant.

This new system, expected to be operational by autumn 2025, will improve energy efficiency by 25% and enhance automation, supporting the company’s commitment to innovation and sustainability. By continuing to use recycled aluminium, Hueck Folien aims to reduce CO2 emissions by 85% and achieve ecologically neutral production by 2035.

Ladakh (Union Territory, located in northern India) has become the first state in India to adopt a sustainable tamper evident holographic tax stamp to prevent illicit liquor trade, protect revenue, and ensure product authentication. It is also noteworthy that Ladakh is using tax stamps for the first time.

These tax stamps are provided by a start- up company, Track Pack Innovation (TPI), under the aegis of the Ministry of Science and Technology, the government of India. The labels are produced on TPI patent technology SSLS®, a 100% biodegradable tamper-evident solution designed to provide a customised holographic tamper message in the face stock when removal is attempted.

This innovative product offers both sustainability and two additional layers of security for brand owners and revenue authorities, enhancing authentication and tax stamp label usage. The top layer features physical and digital security elements, while hidden images, taggants, holograms, and specialised inks are embedded in the label’s reverse side, said officials of TPI.

ID Genève and Morphotonix have collaborated to bring nano-engraving technology into luxury watchmaking in Switzerland. Focused on sustainability and innovation, ID Genève has unveiled its second collection, ‘Elements’, featuring 100% locally recycled stainless steel cases paired with holographic nano- engraved dials.

The Elements collection features five unique dials crafted using Morphotonix’s nano-engraving technology, embedding security features directly into the products without additives, preserving material purity and enabling instant authentication. With 130,000 dpi precision, the dials produce iridescent effects that mimic natural light-diffusing microstructures found in butterflies, beetles, and seashells. The collection offers a matching steel bracelet or a sustainable hemp-based strap.

Backed by Leonardo DiCaprio, ID Genève is known for its commitment to eco- conscious luxury.

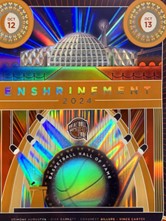

On aesthetic and security packaging development, Hazen Paper’s 12 Enshrinement Yearbook cover for the Naismith Memorial Basketball Hall of Fame in Springfield, Massachusetts, showcases a nice example of trailblazing optically variable visual effects. The very limited- edition 2024 cover, created with Hazen Holojet®, features a free-form fresnel lens image of the Hall of Fame Dome as well as a multi-channel hologram of a floating basketball. Hazen Holojet® is a holographic product that is press-ready and certified for digital print.

Idvac has developed a novel colour- shifting effect on flexible films, achieved without structural embossing, inks, or pigments. Using Fabry-Perot optical principles, it combines vacuum metallising with dielectric coatings for rapid colour changes, such as blue to green or red to green, depending on the angle.

This process utilises Fabry-Perot optical principles to facilitate rapid colour changes.

By combining vacuum metallising with low-index dielectric coatings, the process creates an appealing transition from blue to green, depending on the viewing angle.

The process works at high speeds in standard vacuum web metallisers and can enhance micro-embossed holographic surfaces for added security. It’s ideal for security threads, decorative packaging, and pharmaceutical products and can be printed onto films for quick colour-shifting texts, logos, and patterns.