Holographic displays project 3D images that appear to float in space, without needing special glasses to view. This makes them useful for applications like education, entertainment, and medicine, but current holographic displays suffer from limitations in viewing angle, image sharpness and depth of field.

In this roundup of research into improving the performance of holographic 3D displays we look at three teams that are planning to do just that.

The researchers at the Beihang University, Beijing wanted to create a holographic display with a wider viewing angle so that more people could see the 3D image clearly at the same time.

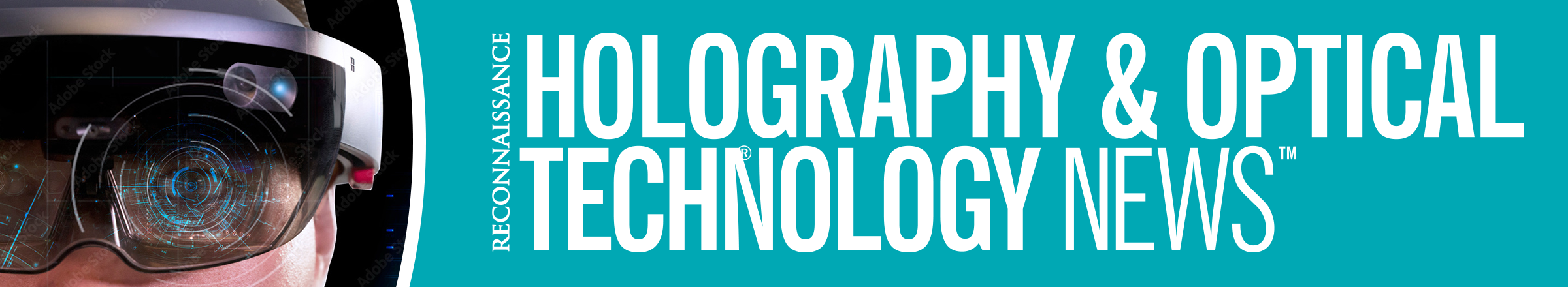

They used a combination of spatial light modulators (SLMs) and liquid crystal gratings in their display system. The researchers calculated the maximum diffraction angle possible from the SLMs based on their limited diffraction range. Using this, they generated larger holographic structures that expanded the range of diffraction angles, allowing for a wider viewing zone.

The liquid crystal gratings further diffracted the reconstructed 3D image light, continuously spreading the viewing angle even more. In testing, this new technique achieved a viewing angle of 73.4 degrees, significantly larger than previous displays registered angles of under 60 degrees.

Structure of liquid crystal grating. a) Distribution of the liquid crystal molecules when the voltage is turned off. b) Distribution of the liquid crystal molecules when the voltage is turned on (© Light: Advanced Manufacturing).

The current study demonstrates the feasibility of expanding the viewing angle, but only uses a single wavelength (monochrome) rather than multiple colours. Due to fabrication constraints, the researchers could not yet demonstrate a full-colour display with corrected chromatic aberration and wide viewing angle.

For a full-colour display, multiple wavelengths of light are needed – red, green, and blue. Secondly, the liquid crystal grating is wavelength-dependent, meaning it diffracts different wavelengths at slightly different angles. When illuminated by white light, this causes a chromatic aberration effect, where the colours are separated and the image distorted.

For the future, the researchers plan to explore solutions to enable wide-viewing angle, multi-colour holographic displays.

The work has been published in ‘Light: Advanced Manufacturing 1’.

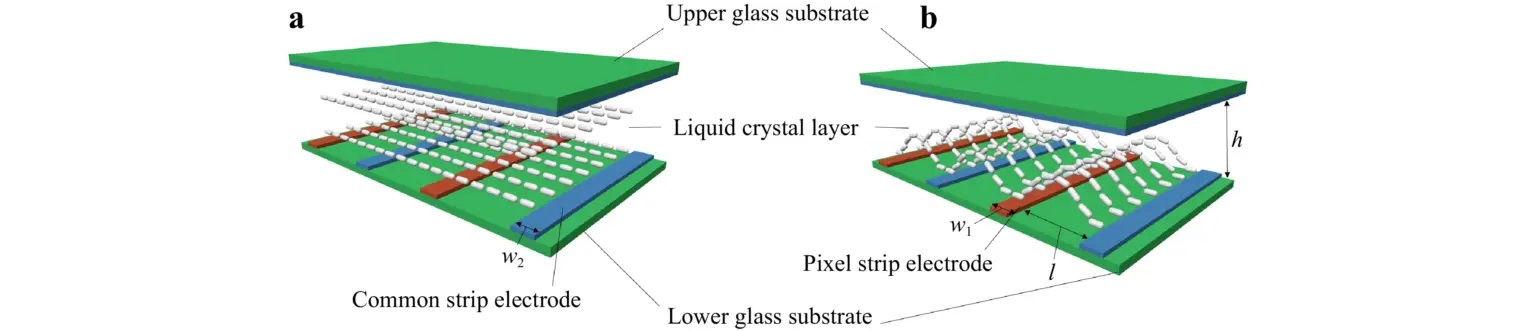

The Center of Photonics and Computational Imaging (CPCI) of the University of Tartu, Estonia, has been developing imaging technologies that have the advantages of holography but only the minimal requirements of direct imaging systems.

In any imaging system, image sharpness and depth of field are intertwined by the f-number (the ratio of the focal length to the diameter of the lens or aperture). A small f-number provides a sharp image for a particular depth and blurs the object at other planes, a high f-number provides a sharp image for many depths.

While the depth of field can be tuned by selecting an appropriate f-number before capturing the image, it is impossible to change the depth of field after recording the picture. The only way to obtain the desired depth of field after recording is to repeat the recording again.

There are computational methods, such as deblurring, that may help to some extent to refocus a slightly blurred image plane digitally. But during this process, an already sharp image becomes blurred. There is no technology available today that has the capability to tune the depth of field after recording.

PhD student Shivasubramanian Gopinath, research manager Aravind Simon, and Prof Vijayakumar Anand have now proposed a solution to this problem through the holographic hybridization method 2.

Instead of recording one picture, they propose recording two pictures collinearly and simultaneously, one with a refractive lens and another with a refractive axicon or a conical prism. A refractive lens has a low depth of field and an axicon has a high depth of field. The two recorded digital pictures are combined with different strengths and reconstructed in the computer by a special algorithm developed at CPCI.

By tuning the strengths of the two pictures before combining them into one, it is possible to tune the depth of field within the limits of the lens and the axicon. The schematic of the setup, the variation of depth of field, and the expected change in the picture are shown in the figure below.

The Fraunhofer Institute for Photonic Microsystems (IPMS), with locations in Dresden, Erfurt and Cottbus (Germany), develops photonic microsystems that modulate light using small, controllable mirrors. These SLMs are micromirror arrays with up to several million mirrors on a semiconductor chip.

In its own laboratories and 1,500 m² clean room, Fraunhofer IPMS develops a wide variety of application specific SLMs based on 200 mm wafer technology. To enable individual deflection of each micromirror, a highly integrated electronic circuit is used as the basis for the component architecture. In combination with monolithically integrated MEMS (Micro Electromechanical Systems) technology, unique micromirror arrays are created. In addition, Fraunhofer IPMS develops the electronics and software to drive the devices.

Fraunhofer IPMS SLMs are used in printed circuit board manufacturing, adaptive optics, astronomy, microscopy and holographic displays.

A completely new field of application for the piston-motion micromirrors of Fraunhofer IPMS is emerging in holography. In contrast to alternative methods such as stereo projection, holographic projection displays allow the virtual representation of objects with a 3D experience identical to that of real objects.

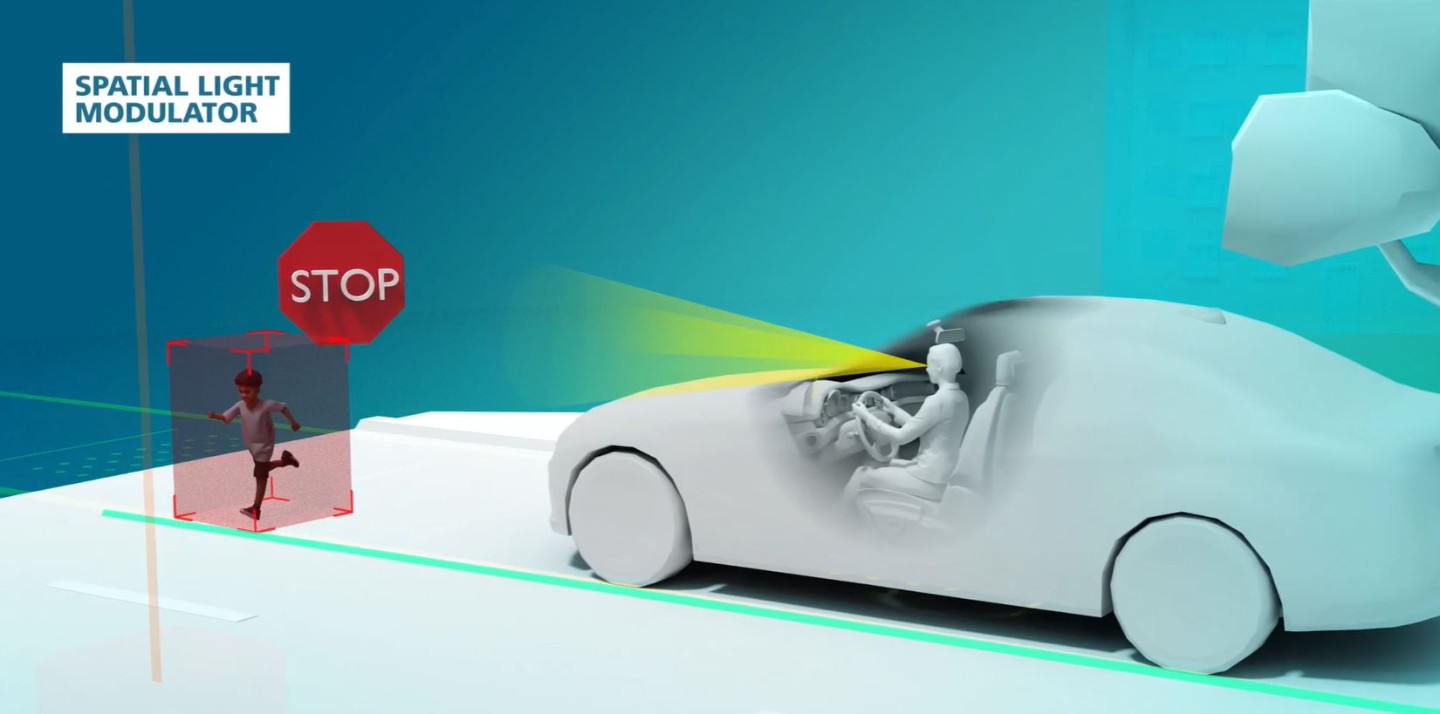

Automotive Head-Up-Display (HUD) (© Fraunhofer IPMS).

Automotive Head-Up-Display (HUD) (© Fraunhofer IPMS).

Fraunhofer IPMS hopes that their micromirror arrays will enable computer-generated holography in the future. Merging real and virtual worlds in motion and in real time. A mirror matrix optimised for holography is currently under development and the first application envisaged is a head-up display (HUD) for automobiles 3.

1 - www.light-am.com/article/doi/10.37188/lam.2023.018

2 - www.sciencedirect.com/science/article/pii/S0143816623003664

3 - www.showroom.leistungszentrum-mikronano.de/#/en/IPMS/IPMS-Automotive